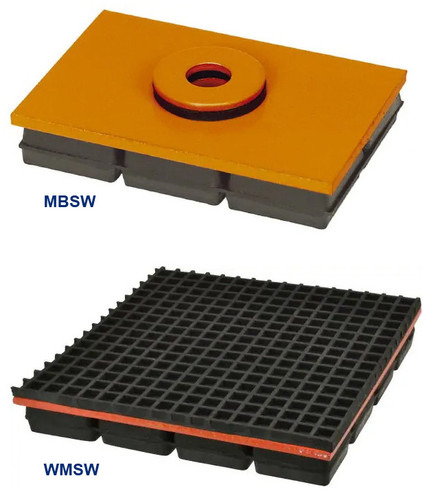

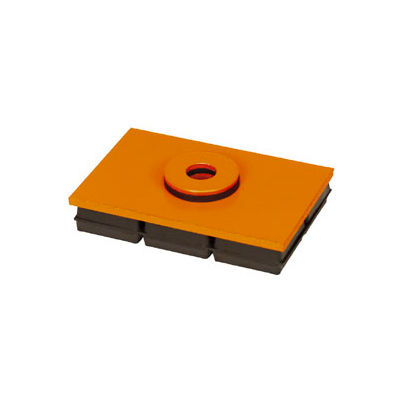

Each 1" (25 mm) thick pad shall be molded using 64 piles of frictioned duck, to a Shore A 90 ±5 durometer.įlexoply pads shall achieve deflection under load by movement of neoprene into fabric pores, rather than relying on neoprene flow or bulge in compression, and shall be capable of supporting up to 10,000 PSI (703 kg per sq.

Model NDF Flexoply isolation pads shall be laminations of neoprene and duck. Special coatings are available for Model NDF Flexoply pads to resist oil saturation. They are resistant to water, brine, fungus and bacterial growth, and produce only a slight swelling in SAE 30 oil. Model NDF Flexoply pads are molded to a Shore A 90 ±5 durometer, have an application temperature range of -35☏ to +200☏ (-37☌ to 93☌), damping characteristic of 14% of critical, and conform to MIL-C-882B Class 1 Specifications. Standard Model NDF Flexoply pads are available in thicknesses as tabulated on the reverse side of this sheet and in sizes and shapes required for each application.

cm) for intermittent loading, and allowable shock loading up to 2,000 PSI (140 kg per sq. The result is allowable loading of up to 10,000 PSI (703 kg per sq. Model NDF Flexoply pads utilize 64 layers per inch (2.6 layers per mm) thickness of laminated neoprene and duck, which allows absorption of shock and vibration by movement of the neoprene in and out of the fabric layers. Model NDF Flexoply isolation pads are a laminated neoprene and cotton duck fabric isolation material developed for use in highly loaded, shock and vibration isolation applications.

0 kommentar(er)

0 kommentar(er)